Rotor resurfacing is a critical aspect of vehicle maintenance that ensures your braking system functions at its best. Over time, the brake rotors in your car can wear down, develop grooves, or even warp due to heat and friction during braking. This wear compromises the smooth interaction between the rotors and brake pads, leading to reduced braking efficiency, annoying noises, and, in some cases, dangerous driving conditions.

Resurfacing, also known as brake rotor machining, involves removing a thin layer of material from the rotor’s surface. This process restores a smooth, even finish, allowing the brake pads to grip effectively. By addressing minor imperfections like scoring and uneven wear, rotor resurfacing helps extend the life of both your rotors and brake pads.

Investing in regular rotor maintenance not only saves money in the long run but also ensures safer driving for you and others on the road.

Signs Indicating the Need for Rotor Resurfacing

Recognizing the signs that your brake rotors need resurfacing is crucial for maintaining a safe and efficient braking system. Here are the most common indicators:

Unusual Noises During Braking

If you hear squealing, grinding, or screeching sounds when applying the brakes, it could indicate uneven or damaged rotor surfaces. These noises occur because the brake pads are not making proper contact with the rotors.

Vibrations Felt in the Brake Pedal or Steering Wheel

When rotors develop uneven spots or warp due to heat, you may feel vibrations or pulsations while braking. This is a telltale sign that the rotor surface needs attention.

Visible Grooves or Scoring on the Rotor Surface

Inspect your rotors for visible lines or grooves. These can form when debris gets trapped between the rotor and brake pad or when the rotor wears unevenly over time.

Discoloration or Heat Spots on the Rotor

Blue or dark-colored spots on the rotor surface are signs of excessive heat. These spots can cause the rotors to lose their effectiveness and may require resurfacing.

Cracks or Excessive Rust Buildup

Small cracks or significant rust can compromise rotor integrity. While minor rust may be removed, deeper damage often necessitates resurfacing or replacement.

Addressing these issues promptly helps restore optimal braking performance and enhances overall vehicle safety.

Factors to Consider Before Resurfacing Rotors

Before deciding to resurface your brake rotors, several key factors should be evaluated to ensure safety, efficiency, and cost-effectiveness:

- Evaluating Rotor Thickness and Manufacturer Specifications

Brake rotors have a minimum thickness specification set by the manufacturer. Resurfacing removes a thin layer of material, so it’s crucial to measure the rotor’s current thickness. If the rotor is too thin after resurfacing, it could warp or fail under heat and pressure, making it unsafe for use. - Assessing the Condition of the Braking Surface

Examine the rotor for deep grooves, cracks, or uneven wear. While minor imperfections can be corrected through resurfacing, severe damage might require a complete replacement. Resurfacing cannot fix structural weaknesses or extensive wear. - Compatibility with Brake Pads

When resurfacing rotors, ensure they remain compatible with the type of brake pads your vehicle uses. An uneven or improperly resurfaced rotor surface can lead to poor brake pad performance, reduced braking efficiency, and accelerated pad wear. - Cost and Time Considerations

Resurfacing is often more cost-effective than replacing rotors, but it’s not always the best choice. If the labor costs or downtime are significant, replacement may be a more practical solution, especially for severely worn rotors. - Safety Implications of Resurfacing vs. Replacing Rotors

While resurfacing can restore a rotor’s functionality, replacement is the safer option when damage is extensive. Resurfacing should only be done if the rotors meet all safety requirements post-machining.

Weighing these factors ensures your braking system remains reliable and safe, avoiding costly repairs or accidents down the line.

Common Rotor Resurfacing Techniques

Rotor resurfacing involves various techniques to restore the brake rotor’s surface and improve its performance. Each method has its specific applications depending on the rotor’s condition and level of wear:

Turning

Turning, or machining, is the most common method of resurfacing rotors. This process uses a brake lathe to remove a thin layer of material from the rotor’s surface. By doing so, it corrects uneven wear, warping, or minor imperfections like grooves and scoring. The lathe spins the rotor while a cutting tool scrapes away the damaged surface, leaving a smooth, even finish. This technique is ideal for rotors that are still within the manufacturer’s thickness specifications but show signs of wear or damage.

Grinding

Grinding is used to eliminate deeper grooves, scoring, or rust buildup that a standard lathe cannot address. This technique involves using abrasive grinding wheels or pads to remove imperfections and restore the rotor’s surface. Grinding provides a finer finish than turning and is often employed for heavy-duty or specialty vehicles where precision is critical. However, it requires careful handling to avoid overheating the rotor, which can lead to warping.

Polishing

Polishing is the final step in rotor resurfacing and is designed to achieve a fine, smooth surface finish. This process reduces friction between the brake pads and rotors, helping to prevent noise such as squeaking or squealing. Polishing also ensures optimal contact between the brake pads and the rotor, which improves braking performance and extends the lifespan of both components.

Each resurfacing technique is chosen based on the rotor’s condition and the desired outcome. Proper resurfacing not only enhances braking efficiency but also contributes to the overall safety and longevity of the braking system.

Equipment Used in Rotor Resurfacing

Rotor resurfacing requires specialized equipment to ensure precision, safety, and efficiency. Below are the essential tools used in the process:

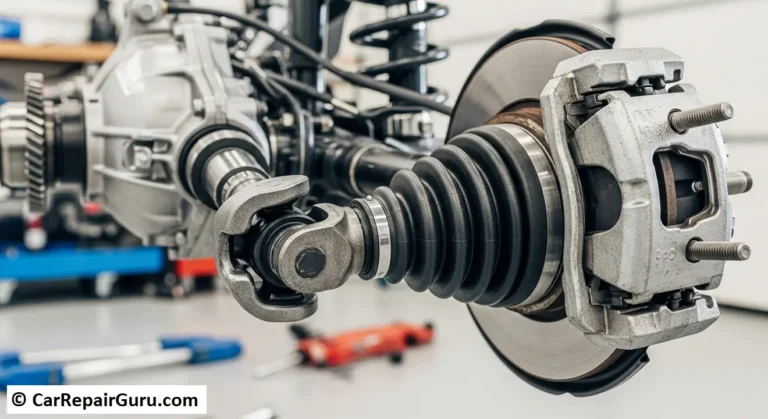

Brake Lathes for Material Removal

Brake lathes are the cornerstone of rotor resurfacing. These machines rotate the rotor while a cutting tool removes a thin layer of material from its surface. This process corrects uneven wear, grooves, and minor warping. There are two types of brake lathes: on-car lathes, which work directly on the rotor while it remains mounted on the vehicle, and off-car lathes, where the rotor is removed for machining. Both provide a smooth, even finish that ensures optimal brake performance.

Measuring Instruments like Micrometers and Dial Gauges

Precision is critical in rotor resurfacing, and measuring tools like micrometers and dial gauges play a vital role. Micrometers measure the rotor’s thickness to ensure it meets the manufacturer’s minimum specifications after resurfacing. Dial gauges check for lateral runout, or wobbling, to ensure the rotor spins evenly without vibrations.

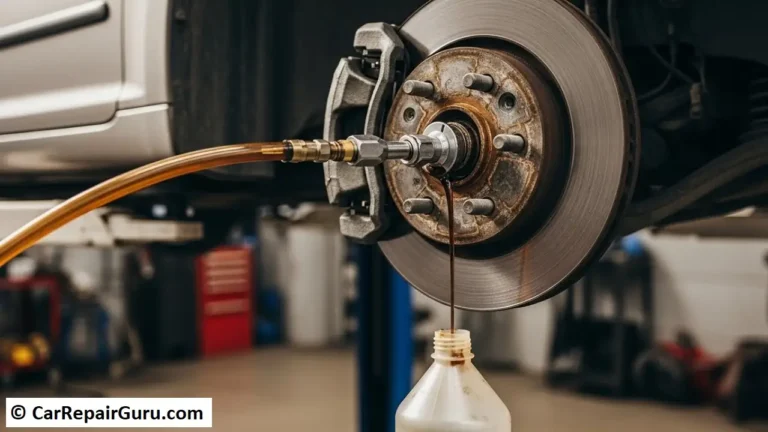

Cleaning Tools to Eliminate Contaminants

Proper cleaning of the rotor before and after resurfacing is essential. Tools like wire brushes, brake cleaner sprays, and compressed air are used to remove rust, debris, and contaminants. This step ensures a smooth machining process and prevents contamination from affecting the brake pads.

Using the right equipment ensures accurate resurfacing, prolonging rotor life and enhancing braking safety.

Benefits of Properly Resurfaced Rotors

Properly resurfaced rotors provide several advantages that enhance the overall performance and safety of your vehicle’s braking system:

Extended Brake Pad Lifespan

Resurfaced rotors create a smooth, even surface that allows brake pads to make consistent contact during braking. This reduces uneven wear on the pads, preventing premature replacement. By eliminating imperfections like grooves or rough spots, the rotors help distribute the braking force evenly, extending the life of your brake pads and saving you money on frequent replacements.

Improved Braking Performance and Safety

A well-resurfaced rotor restores optimal braking efficiency by ensuring proper interaction with the brake pads. This results in better stopping power, reduced braking distances, and improved control in emergency situations. With smoother rotor surfaces, your vehicle’s braking system performs as intended, ensuring the safety of you and your passengers, especially in challenging driving conditions.

Reduction in Noise and Vibrations During Braking

Uneven or damaged rotors often cause squeaking, grinding, or pulsations when braking. Resurfacing eliminates these issues by restoring a uniform surface, reducing friction irregularities, and ensuring a quieter, smoother braking experience. The elimination of vibrations also enhances overall driving comfort.

By investing in rotor resurfacing when needed, you maintain your vehicle’s braking efficiency, improve safety, and reduce long-term maintenance costs.

When to Replace Instead of Resurfacing Rotors

While rotor resurfacing can restore functionality in many cases, there are situations where replacement is a safer and more practical option:

- Rotors Below Minimum Thickness Specifications

Each rotor has a manufacturer-defined minimum thickness that ensures structural integrity and safe operation. Resurfacing removes a layer of material, and if the rotor is already close to or below this limit, it should be replaced. Operating with excessively thin rotors increases the risk of overheating, warping, or even failure under stress. - Presence of Deep Cracks or Severe Damage

Small surface imperfections can be corrected through resurfacing, but deep cracks or severe damage compromise the rotor’s structural integrity. Cracked rotors are unsafe, as they can break under pressure, leading to brake failure. Replacement is the only viable option in such cases. - Excessive Warping or Heat Damage

Rotors that have warped significantly or developed large heat spots due to overheating cannot be effectively resurfaced. These conditions cause uneven braking and reduced performance. Replacement ensures a smooth and reliable braking experience. - Cost-Effectiveness of Replacement vs. Resurfacing

In some cases, the cost of resurfacing may approach or exceed the price of new rotors, especially for vehicles with inexpensive aftermarket options. Additionally, resurfacing requires labor and time, while replacement offers a quicker, more efficient solution.

Choosing to replace rather than resurface ensures optimal braking performance and long-term reliability, especially when safety and cost considerations align.

Conclusion

Maintaining your vehicle’s brake rotors is essential for ensuring safety, optimal performance, and a smooth driving experience. Proper rotor care, whether through resurfacing or replacement, prevents costly repairs, extends the lifespan of your brake pads, and enhances overall braking efficiency. Recognizing the signs of wear, understanding when to resurface or replace, and using appropriate techniques all contribute to a reliable braking system.

While some rotor maintenance tasks can be assessed visually, determining the best course of action often requires professional expertise. Certified technicians have the tools and knowledge to measure rotor thickness, assess wear patterns, and recommend the safest and most cost-effective solution.

Don’t compromise on safety—if you notice unusual noises, vibrations, or reduced braking performance, consult a professional for a thorough inspection. Regular rotor maintenance ensures your vehicle remains safe on the road while offering peace of mind for you and your passengers.

FAQs about Rotor Resurfacing

What is rotor resurfacing?

It’s the process of machining the brake rotor surface to remove imperfections and restore smoothness.

How do I know if my rotors need resurfacing?

Look for signs like squealing, vibrations, visible grooves, discoloration, or cracks.

Can all rotors be resurfaced?

No. It depends on rotor thickness, damage level, and manufacturer guidelines.

How often should rotors be resurfaced?

There’s no set time. It depends on wear, driving habits, and brake inspections.

Is rotor resurfacing cost-effective?

Yes, if the rotors are still in good shape. If damage is severe, replacement is better.