Imagine driving on a bumpy road without a functioning suspension system—every dip and crack would send jolts through your car, making for an uncomfortable and even dangerous ride. The car suspension system plays a crucial role in ensuring a smooth, controlled, and stable driving experience. It consists of key components like shock absorbers, springs, control arms, and bushings, all working together to absorb road shocks, maintain tire contact, and enhance vehicle handling.

Regular car suspension testing is essential for vehicle safety and performance. Over time, suspension components wear out, affecting ride comfort, steering responsiveness, and even braking efficiency. Ignoring suspension issues can lead to uneven tire wear, reduced fuel efficiency, and a higher risk of accidents. By conducting routine suspension checks, you can identify potential problems early, prevent costly repairs, and ensure a safer, more comfortable driving experience.

Does this align with your expectations? Let me know if you’d like any adjustments before proceeding to the next section!

Key Components of a Car Suspension System

A car’s suspension system is designed to absorb road impacts, enhance stability, and provide a smooth ride. It consists of several key components, each playing a crucial role in maintaining comfort and handling.

- Springs: These are the backbone of the suspension system, responsible for absorbing shocks from the road. There are different types, including coil springs, leaf springs, and air springs, all designed to support the vehicle’s weight and provide flexibility when driving over uneven surfaces.

- Shock Absorbers: Also known as dampers, shock absorbers control the movement of the springs and prevent excessive bouncing. They work by converting kinetic energy from road impacts into heat, which is then dissipated, ensuring a stable and comfortable ride.

- Control Arms: These metal links connect the suspension system to the vehicle’s frame, allowing the wheels to move up and down independently while keeping them properly aligned. They play a critical role in steering and handling precision.

- Bushings: Made of rubber or polyurethane, bushings cushion the contact points between suspension components, reducing vibrations and minimizing friction. They help prevent wear and tear while contributing to a smoother driving experience.

Together, these components work harmoniously to enhance vehicle stability, improve handling, and ensure optimal comfort on the road.

Common Signs of Suspension Problems

Your car’s suspension system is built to handle rough roads, but over time, wear and tear can lead to performance issues. Ignoring these problems can compromise safety, handling, and ride comfort. Here are the most common signs that your suspension system may need attention:

- Unusual Noises

If you hear clanking, knocking, or squeaking when driving over bumps, it could indicate worn-out shock absorbers, bushings, or control arms. These noises often mean metal parts are rubbing together due to loose or damaged suspension components. - Vehicle Pulling to One Side

If your car drifts or pulls in one direction while driving, it could signal an issue with uneven suspension wear, misaligned wheels, or failing control arms. This problem can reduce steering control and increase tire wear. - Uneven Tire Wear

Suspension problems can cause irregular or excessive tire wear, particularly cupping or bald spots. This is often due to misaligned wheels, faulty shocks, or worn suspension parts that fail to keep the tires in full contact with the road. - Excessive Bouncing

If your car continues bouncing after hitting a bump, it may indicate worn shock absorbers or damaged springs. A simple bounce test—pushing down on the hood and observing how many times it bounces—can help determine if shocks need replacement. - Difficulty Steering

A stiff or unresponsive steering wheel could point to suspension issues, such as failing control arms, worn bushings, or damaged power steering components. If turning feels rough or delayed, it’s time for an inspection.

Addressing suspension problems early can improve ride quality, extend tire life, and enhance overall driving safety. If you notice any of these symptoms, have your suspension system checked by a professional.

Methods of Car Suspension Testing

Regular car suspension testing is crucial for maintaining vehicle stability, ride comfort, and overall safety. There are several methods used to assess the condition of suspension components, ranging from simple manual checks to advanced diagnostic tools.

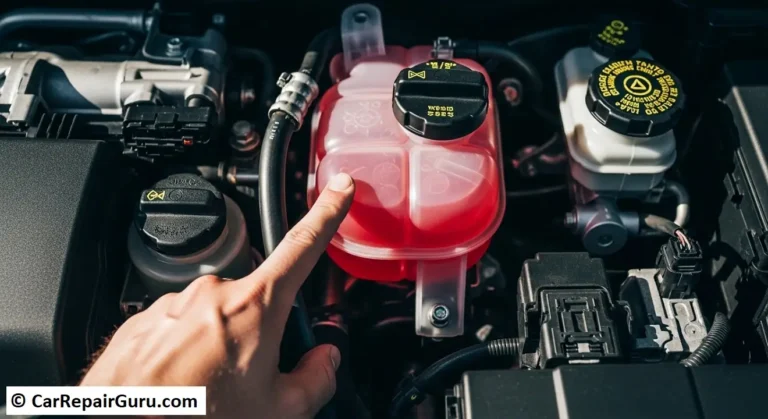

1. Visual Inspection

A visual check is the first step in suspension testing. This involves examining key components like shock absorbers, springs, control arms, and bushings for visible signs of wear or damage. Common issues include:

- Leaking shock absorbers (a sign of failure).

- Cracked or sagging springs.

- Worn-out or torn bushings.

- Rust, corrosion, or bent parts.

A mechanic may also inspect for loose bolts or any unusual misalignment in the system.

2. Bounce Test

A simple yet effective way to test shock absorber performance is the bounce test. To perform it:

- Firmly press down on one corner of the vehicle.

- Release and observe how many times it bounces.

- If the car continues bouncing more than twice, the shock absorbers are likely worn out and need replacement.

3. Dynamic Load Testing

This method simulates real-world driving conditions to evaluate how the suspension system responds to bumps, turns, and sudden stops. A mechanic may take the car for a test drive and check for:

- Excessive body roll during turns.

- Delayed response in steering.

- Abnormal noises (clunking, knocking, or squeaking).

- Poor road grip or instability.

4. Static Load Testing

Unlike dynamic testing, static load testing assesses the suspension’s ability to support the vehicle’s weight while stationary. This test is performed by:

- Measuring the height of each corner of the car to ensure even weight distribution.

- Checking for sagging springs or an unbalanced stance.

- Inspecting the shock absorber compression when additional weight is applied to the car.

5. Advanced Diagnostic Tools

For a more precise analysis, professionals use high-tech diagnostic equipment, including:

- Vibration analyzers: Detect irregular vibrations caused by suspension issues.

- Load sensors: Measure weight distribution and pressure on each suspension component.

- Wheel alignment systems: Ensure proper alignment, reducing tire wear and improving handling.

By combining these suspension testing methods, mechanics can accurately diagnose issues and recommend necessary repairs, ensuring a safer, smoother, and more stable driving experience.

Importance of Regular Car Suspension Testing

A well-maintained suspension system is essential for a safe, smooth, and efficient driving experience. Regular car suspension testing helps identify potential issues before they escalate into major problems, ensuring optimal performance and safety.

1. Ensuring Vehicle Safety

A faulty suspension system can significantly reduce vehicle control, especially when braking or navigating curves. Worn-out shock absorbers, springs, or bushings can lead to:

- Increased stopping distances, making sudden braking less effective.

- Unstable handling, raising the risk of rollovers or loss of control.

- Excessive body roll during turns, compromising safety.

Routine suspension checks help prevent potential failures, keeping you and other road users safe.

2. Enhancing Ride Comfort & Handling

A properly functioning suspension system absorbs shocks from road imperfections, ensuring a smooth ride. Regular testing prevents:

- Excessive bouncing or vibrations caused by worn shocks.

- Steering instability, making it harder to control the vehicle.

- Uneven weight distribution, leading to driver fatigue on long journeys.

By maintaining optimal suspension performance, you enjoy better steering response, improved road grip, and a more comfortable ride.

3. Prolonging Tire & Component Lifespan

Suspension problems can cause irregular tire wear, reducing tire lifespan and increasing fuel consumption. Misaligned wheels, damaged shocks, or faulty springs can lead to:

- Uneven tread wear, requiring premature tire replacements.

- Excessive strain on other components, such as wheel bearings and control arms.

Regular suspension testing prevents unnecessary damage, saving you money on repairs and replacements.

4. Maintaining Compliance with Safety Standards

Many countries have strict vehicle safety regulations, requiring cars to pass suspension and alignment inspections. Regular testing ensures compliance by:

- Detecting alignment issues that affect stability.

- Ensuring shocks and struts meet safety standards.

- Avoiding fines or vehicle restrictions due to failed safety checks.

By prioritizing suspension maintenance, you enhance safety, comfort, and cost efficiency, making every drive smoother and more reliable.

Professional vs. DIY Suspension Testing

When it comes to car suspension testing, both DIY methods and professional inspections play a role in ensuring a safe and smooth ride. While car owners can perform basic checks at home, professional testing provides a detailed, accurate diagnosis that helps prevent long-term damage.

DIY Suspension Testing

Car owners can conduct simple tests to identify early signs of suspension problems. These include:

- Visual Inspection: Checking for leaking shocks, cracked bushings, or worn-out springs.

- Bounce Test: Pushing down on each corner of the vehicle and observing the rebound. If the car bounces more than twice, the shock absorbers may be worn out.

- Listening for Noises: Clunking, squeaking, or knocking sounds when driving over bumps may indicate loose or damaged components.

While DIY testing helps detect obvious issues, it has limitations and may not reveal deeper mechanical faults.

Professional Suspension Testing

Certified mechanics use advanced tools to conduct comprehensive suspension diagnostics, including:

- Computerized Wheel Alignment: Ensures wheels are perfectly aligned, preventing uneven tire wear.

- Load & Vibration Testing: Uses specialized sensors to measure suspension response under different driving conditions.

- Dynamic Road Testing: A real-world test to evaluate handling, stability, and ride comfort.

Why Choose Professional Suspension Testing? 🚘✅

Seeking professional assistance ensures:

✔ Accurate diagnosis of hidden suspension issues.

✔ Proper repairs using specialized tools and expertise.

✔ Increased safety, preventing potential breakdowns and accidents.

While DIY tests are useful for early detection, professional suspension testing guarantees precision and long-term vehicle performance.

Future Trends in Suspension Testing

As automotive technology advances, suspension testing is evolving to become more precise, efficient, and predictive. Innovations in AI diagnostics, advanced testing equipment, and real-time monitoring are shaping the future of vehicle suspension assessments.

1. AI-Powered Diagnostic Tools

Artificial intelligence (AI) is revolutionizing vehicle diagnostics by enabling automated suspension analysis. AI-powered tools can:

- Detect suspension issues in real time by analyzing driving patterns and vehicle responses.

- Use machine learning algorithms to predict potential failures before they occur.

- Provide data-driven recommendations for maintenance, reducing repair costs.

2. Advanced Testing Equipment & Software Solutions

New-generation suspension testing machines offer:

- High-speed laser scanners to measure component wear with extreme precision.

- Digital suspension simulators that replicate real-world conditions for detailed testing.

- Cloud-based diagnostic platforms, allowing remote monitoring and assessment.

3. Predictive Maintenance & Continuous Monitoring

Modern vehicles are incorporating smart sensors that continuously track suspension health. These systems:

- Detect early signs of wear and misalignment before they become critical.

- Send real-time alerts to drivers and service centers.

- Enhance vehicle longevity, efficiency, and safety by ensuring proactive maintenance.

As AI, automation, and smart monitoring become standard, suspension testing will shift from reactive maintenance to predictive, data-driven solutions, improving both vehicle performance and driver safety.

Conclusion

Regular car suspension testing is vital for ensuring your vehicle’s safety, comfort, and performance. By staying proactive with suspension maintenance, you can prevent potential issues like unstable handling, excessive tire wear, and unsafe driving conditions. Whether through DIY checks or professional diagnostics, identifying suspension problems early can save you from costly repairs and enhance your overall driving experience.

Taking the time to inspect shock absorbers, springs, control arms, and other key components ensures that your suspension system continues to function optimally, providing a smooth and stable ride. Embracing modern testing methods like AI diagnostics and predictive maintenance will further boost safety and extend the life of your vehicle.

Remember, preventative maintenance is always better than dealing with sudden breakdowns. Stay proactive and keep your suspension system in check to ensure a safe, smooth, and comfortable ride for years to come.

suspension testing FAQ

Q1: How often should I perform car suspension testing?

It’s recommended to have your vehicle’s suspension inspected every 12,000 miles or annually, whichever comes first. If you notice signs of problems like unusual noises or handling issues, get it checked immediately.

Q2: Can I perform suspension testing myself?

Yes, basic tests like visual inspections and bounce tests can be done by car owners to spot obvious issues. For a more thorough evaluation, especially with ongoing problems, consult a professional.

Q3: What are the risks of neglecting regular suspension testing?

Neglecting suspension testing can lead to poor handling, increased tire wear, and potential suspension failure, which affects both vehicle performance and safety.

Q4: How can suspension problems affect my tires?

Worn suspension components can cause uneven tire wear, reducing tire lifespan and compromising grip, which leads to increased fuel consumption and a bumpy ride.

Q5: Will suspension problems impact my vehicle’s fuel efficiency?

Yes, damaged suspension can increase rolling resistance, causing the engine to work harder, which may reduce fuel efficiency and increase operating costs.