Driving has become significantly smoother and less strenuous thanks to power steering systems. Gone are the days of grappling with a heavy steering wheel, especially during parking or tight turns. Modern vehicles primarily utilize two advanced technologies to provide this steering assistance: the long-established hydraulic power steering (HPS) and the increasingly common electric power steering (EPS).

Hydraulic systems rely on pressurized fluid, offering a traditional feel many drivers appreciate. Electric systems, conversely, use an electric motor, bringing advantages in efficiency and integration with modern vehicle tech. Each system possesses distinct characteristics, impacting everything from driving feel and vehicle performance to fuel economy and maintenance needs.

This article compares hydraulic and electric steering technologies, diving into their mechanisms, advantages, and disadvantages. Whether you’re a car enthusiast keen on handling dynamics or a buyer weighing vehicle features, this guide will clarify the differences between these essential automotive systems.

- Unpacking Hydraulic Power Steering (HPS)

- How Hydraulic Steering Works

- The Appeal of Hydraulic Systems

- Considerations with Hydraulic Steering

- Exploring Electric Power Steering (EPS)

- How Electric Steering Works

- The Advantages of Electric Systems

- Potential Downsides of Electric Steering

- Hydraulic vs. Electric Steering: A Head-to-Head Comparison

- Future Directions in Steering Technology

- Conclusion: Choosing the Right Steering System

- FAQs

Unpacking Hydraulic Power Steering (HPS)

How Hydraulic Steering Works

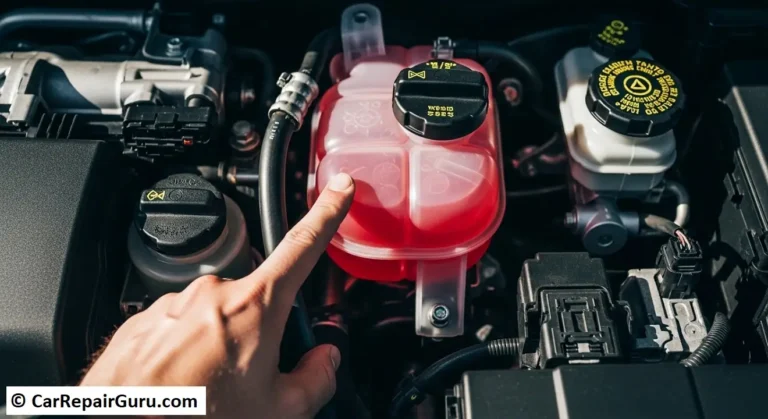

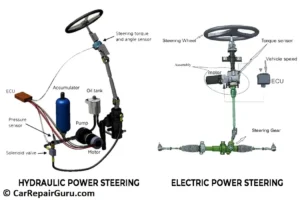

Hydraulic power steering has been a mainstay in automotive design for decades. Its operation centers around hydraulic fluid pressurized by a pump, which is typically driven by the engine’s crankshaft via a belt.

Key Components: The system includes a hydraulic pump, steering gear (often a rack-and-pinion setup), control valves, high-pressure hoses, and a fluid reservoir.

Mechanism: When you turn the wheel, valves direct the pressurized fluid to assist the movement of the steering gear, reducing the physical effort required from the driver.

The Appeal of Hydraulic Systems

Direct Road Feel: One of HPS’s most lauded traits is the steering feedback it provides. Drivers often feel a more direct connection to the road surface, which is highly valued in performance driving scenarios.

Proven Track Record: Having been used for decades across countless vehicle types, HPS is known for its robustness and reliability, especially under heavy loads (common in trucks and larger SUVs).

Consistent Assist: It generally provides smooth and consistent assistance across different driving situations.

Considerations with Hydraulic Steering

Energy Consumption: The hydraulic pump runs continuously whenever the engine is on, even when you’re driving straight and not actively steering. This constant operation draws power from the engine, negatively impacting overall fuel efficiency.

Maintenance Requirements: HPS systems require regular checks. The hydraulic fluid can degrade or leak over time, and components like pumps, belts, and hoses can wear out, potentially leading to costly steering system repairs.

Weight and Complexity: The pump, reservoir, fluid, and hoses add weight and take up space in the engine bay.

Exploring Electric Power Steering (EPS)

How Electric Steering Works

Electric power steering represents a more modern approach to steering assistance, prioritizing efficiency and adaptability. Instead of hydraulic pressure, EPS utilizes an electric motor.

Key Components: The core parts include an electric motor (mounted on the steering column or steering rack), torque sensors, an Electronic Control Unit (ECU), and the steering gear itself.

Mechanism: Sensors detect the driver’s input on the steering wheel (torque and rotation). The ECU processes this information, along with vehicle speed, and commands the electric motor to provide the appropriate level of assistance.

The Advantages of Electric Systems

Enhanced Fuel Economy: This is a major benefit. The electric motor only consumes significant power when steering assistance is needed, reducing the parasitic drag on the engine compared to a constantly running hydraulic pump. This contributes directly to better miles per gallon (MPG).

Integration with Modern Tech: EPS is crucial for enabling many Advanced Driver-Assistance Systems (ADAS). Features like lane-keeping assist, automated parking, and stability control adjustments rely heavily on the precise electronic control offered by EPS.

Variable Assistance Levels: The ECU can easily adjust the amount of steering assist based on vehicle speed. More assist is provided at low speeds (e.g., parking), and less assist at higher speeds for better stability and feel.

Reduced Maintenance: With no hydraulic fluid to leak or replace, and no pumps or belts to maintain, EPS systems generally require less upkeep.

Simpler Design & Less Weight: The absence of hydraulic components makes EPS systems lighter and more compact, benefiting vehicle packaging and overall weight reduction.

Potential Downsides of Electric Steering

Steering Feel & Feedback: Early EPS systems were often criticized for feeling numb or artificial, lacking the nuanced road feedback of good hydraulic systems. While modern EPS has improved significantly, some driving purists still prefer the HPS feel.

Repair Costs: While generally reliable, if an electronic component like the motor, sensor, or ECU fails, repair costs can sometimes be higher than fixing a traditional hydraulic component.

Electrical System Dependency: Performance relies entirely on the vehicle’s electrical system. Issues like a weak battery or faulty wiring can directly impact steering function.

Hydraulic vs. Electric Steering: A Head-to-Head Comparison

Let’s directly compare these two steering technologies across key areas:

| Feature | Hydraulic Power Steering (HPS) | Electric Power Steering (EPS) | Key Takeaway |

|---|---|---|---|

| Steering Feel | Generally provides more natural, direct feedback. | Can feel less connected (though improving rapidly). | HPS often preferred by performance enthusiasts. |

| Fuel Efficiency | Lower; pump runs constantly, drawing engine power. | Higher; motor uses power only when assisting. | EPS offers clear fuel economy benefits. |

| Maintenance | Requires fluid checks/changes, potential leaks. | Largely maintenance-free (no fluid, pumps, hoses). | EPS is simpler and cheaper to maintain. |

| Complexity | More mechanical components (pump, hoses, fluid). | More electronic components (motor, sensors, ECU). | Complexity shifts from mechanical to electronic. |

| Weight | Heavier due to additional components and fluid. | Lighter and more compact. | EPS contributes to vehicle weight reduction. |

| ADAS Integration | Limited or non-existent. | Essential for modern driver-assist features. | EPS is vital for advanced safety/convenience tech. |

| Reliability | Proven track record, but more wear points. | Generally reliable, fewer mechanical wear points. | Both are reliable, but failure modes differ. |

| Cost | Lower initial component cost (traditionally). | Potentially higher initial cost, but lower running cost. | Repair costs for EPS electronics can be higher. |

Future Directions in Steering Technology

The evolution of automotive steering systems isn’t stopping. Key trends include:

Steer-by-Wire: This futuristic technology eliminates the physical connection (steering shaft) between the steering wheel and the wheels altogether. Steering inputs are transmitted electronically, offering ultimate control, design flexibility (e.g., stowable steering wheels for autonomous cars), and further potential for ADAS integration.

Advanced EPS Tuning: Manufacturers are continuously refining EPS systems to better mimic the desirable feedback characteristics of hydraulic setups while retaining efficiency benefits. Sophisticated algorithms are making electric steering feel more natural and engaging.

Phasing Out HPS: Due to fuel efficiency regulations and the push towards electrification and ADAS, hydraulic systems are becoming less common in new passenger cars, likely remaining primarily in heavy-duty applications or specific niche performance vehicles for the foreseeable future.

Conclusion: Choosing the Right Steering System

Both hydraulic power steering and electric power steering effectively reduce steering effort, but they do so differently, bringing unique pros and cons.

HPS offers a classic, connected driving feel and proven robustness, often favoured in performance cars and heavy vehicles, despite its lower efficiency and higher maintenance needs.

EPS stands out for its fuel efficiency, low maintenance, adaptability, and crucial role in enabling modern driver-assistance features, making it the standard in most new passenger cars, hybrids, and EVs.

Understanding the core differences in feel, efficiency, maintenance, and technology integration helps explain why manufacturers choose one over the other and can inform your own preferences when considering a vehicle. As technology advances, particularly with EPS and steer-by-wire, the driving experience will continue to evolve.

FAQs

Q1: What’s the simplest way to explain the difference between hydraulic and electric power steering?

A: Hydraulic uses fluid pressure generated by an engine-driven pump for assist; Electric uses an electric motor controlled by sensors and a computer.

Q2: Which power steering system saves more gas?

A: Electric power steering (EPS) is significantly more fuel-efficient because it only uses energy when you’re actually turning the wheel.

Q3: Do electric power steering systems feel numb compared to hydraulic?

A: Early EPS systems often did, but modern versions have greatly improved. While some purists still prefer the directness of HPS, many current EPS systems offer good feedback and variable assist tailored to driving speed.

Q4: What kind of maintenance does each type require?

A: Hydraulic systems need periodic checks of fluid levels and condition, plus inspection of belts and hoses for leaks or wear. Electric systems generally require no specific routine maintenance.

Q5: Is one steering system more reliable?

A: Both are generally reliable. HPS has a long history but more mechanical parts that can wear or leak. EPS has fewer moving parts but relies on complex electronics that can be costly to fix if they fail.