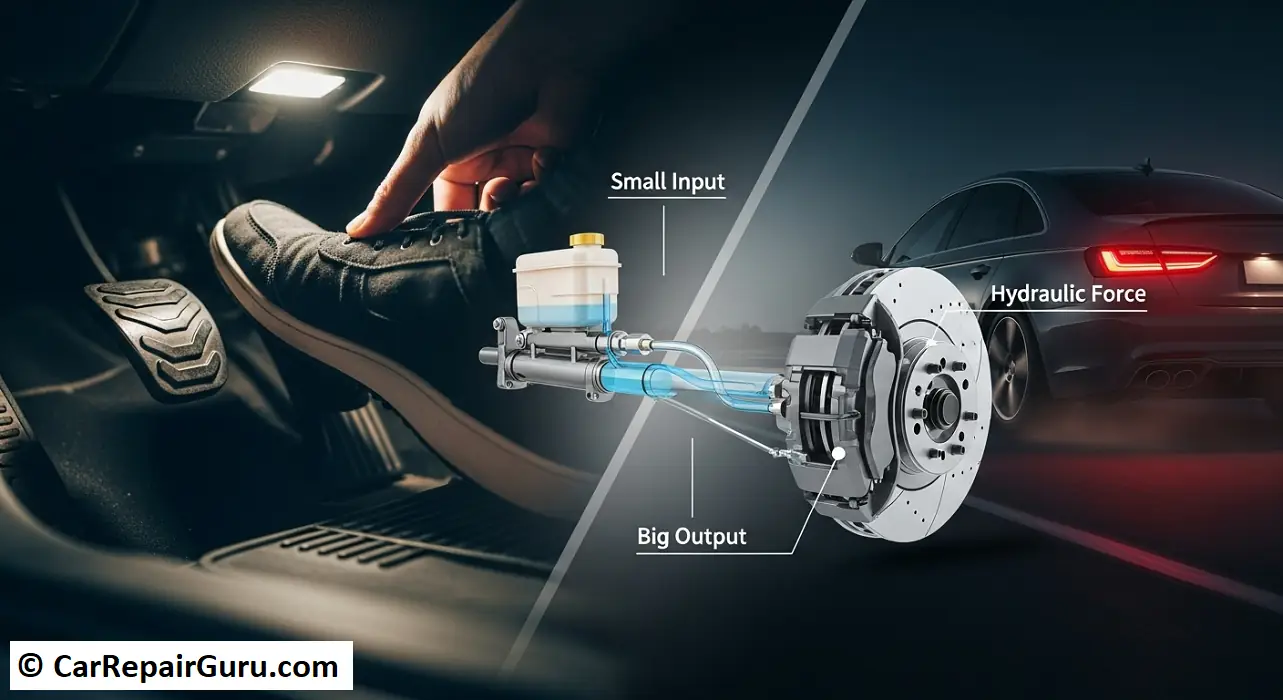

Ever wondered how your car stops so smoothly or turns with such little effort? The answer lies in its hydraulic systems—the hidden force behind your brakes, steering, and suspension.

These systems use pressurized fluid to transfer a small action, like pressing the brake pedal, into a powerful result, like stopping a two-ton vehicle. Understanding how they work and how to maintain them is key to keeping your car safe, responsive, and reliable on the road.

- Key Components of Hydraulic Systems in Cars

- Hydraulic Pump

- Hydraulic Fluid

- Actuators

- Reservoir

- Common Issues with Hydraulic Systems in Cars

- Fluid Leaks

- Contamination

- Pressure Loss

- Best Practices for Maintaining Hydraulic Systems in Cars

- Regular Fluid Checks

- Inspect Hydraulic Hoses and Connections

- Monitor System Pressure

- Hydraulic Fluid Replacement

- Maintenance Schedule for Hydraulic Systems in Cars

- Safety Precautions During Hydraulic System Maintenance

- A Final Word on Safety

- Frequently Asked Questions

- What do hydraulic systems do in a car?

- How do I know if my hydraulic system is failing?

- How often should I change my car’s hydraulic fluid?

- Can I fix a hydraulic leak myself?

Key Components of Hydraulic Systems in Cars

To fully understand how hydraulic systems in cars work, it’s essential to know the main components that make them function efficiently. Each part plays a vital role in delivering the power needed for smooth and safe vehicle operation.

Hydraulic Pump

The hydraulic pump is the heart of the system. It takes mechanical energy from the engine and converts it into hydraulic energy by pushing fluid through the system. This pressurized fluid is what powers critical systems like the hydraulic car braking system, steering, and suspension. Without a functioning pump, the system wouldn’t have the force it needs to operate.

Hydraulic Fluid

Acting as the lifeblood of the system, hydraulic fluid transfers power between components. It also lubricates parts and helps with heat dissipation. Proper hydraulic fluid maintenance is essential—not only to ensure smooth performance but to prevent hydraulic fluid leaks in cars. Low or contaminated fluid can lead to system failure, so checking fluid levels regularly is a must.

Actuators

Hydraulic actuators in cars convert the pressure of the fluid into mechanical force. These actuators are found in various parts of the vehicle, including brake calipers and power steering systems. They allow your small inputs—like pressing a pedal or turning the wheel—to translate into powerful, controlled actions.

Reservoir

The hydraulic fluid reservoir holds excess fluid and keeps it clean and ready for circulation. It also helps regulate fluid pressure throughout the system. A healthy reservoir ensures the system remains pressurized and responsive under varying driving conditions.

Together, these components form a tightly integrated network that allows hydraulic systems in cars to perform flawlessly.

Common Issues with Hydraulic Systems in Cars

Like any critical system in a vehicle, hydraulic systems in cars can experience issues over time—especially if not properly maintained. Recognizing common problems early can prevent costly repairs and keep your vehicle running smoothly.

Fluid Leaks

One of the most common problems is hydraulic system fluid leaks. These can occur due to worn-out hoses, damaged seals, or corroded connections. Even a small leak can reduce system pressure and compromise performance—especially in safety-critical components. Early signs of a leak include puddles under the vehicle, a soft brake pedal, or difficulty steering.

Contamination

Hydraulic fluid contamination is another major concern. Dirt, moisture, or metal shavings can enter the system, causing internal damage and reducing efficiency. Contaminated fluid often appears dark or milky. To detect issues, inspect the hydraulic fluid regularly and replace it if it looks dirty or has a burnt smell. Clean fluid is essential for preserving the life of automotive hydraulic components.

Pressure Loss

Low hydraulic pressure in car systems can result from leaks, pump failure, or air in the system. A sudden loss of pressure may cause brakes to feel spongy or steering to become unresponsive. Regular pressure checks and prompt repairs are crucial for maintaining safety and performance.

By addressing these issues early, you can extend the life of your hydraulic system and avoid unexpected breakdowns.

Best Practices for Maintaining Hydraulic Systems in Cars

Proper care of your hydraulic systems in cars is essential for long-term performance, safety, and preventing unexpected failures. Following these best practices ensures your vehicle’s hydraulic functions—like braking, steering, and suspension—remain smooth and responsive.

Regular Fluid Checks

The first and most important step is regular hydraulic fluid maintenance. Check the fluid level at least once a month, or more frequently if you drive under heavy conditions. Low fluid can indicate a hydraulic fluid leak, which should be addressed immediately. In addition to checking the level, inspect the fluid’s condition. Healthy hydraulic fluid should be clear with a slight amber tint. If it looks dark, cloudy, or has particles in it, it may be contaminated and require replacement.

Inspect Hydraulic Hoses and Connections

Hydraulic hoses are the arteries of the system. Over time, they can crack, swell, or loosen, leading to leaks or reduced pressure. Regularly inspect all hydraulic hoses for vehicles for signs of wear, damage, or corrosion. Make sure clamps and fittings are tight and free from residue. This simple step can prevent larger issues before they develop.

Monitor System Pressure

Maintaining the correct pressure in your automotive hydraulic systems is key to performance. A drop in pressure can cause braking or steering issues and even total system failure. Use a pressure gauge to test the system periodically, especially if you’re noticing performance changes. This is particularly important for vehicles with hydraulic steering systems or braking systems.

Hydraulic Fluid Replacement

Even with proper care, hydraulic fluid needs to be replaced periodically. As a rule of thumb, change the fluid every 30,000 to 60,000 miles, or as specified by your vehicle’s manual. Always use the recommended type of hydraulic fluid to ensure compatibility and performance.

By incorporating these maintenance steps, you’ll extend the life of your car’s hydraulic system and avoid costly repairs down the road.

Maintenance Schedule for Hydraulic Systems in Cars

To keep hydraulic systems in cars running efficiently, it’s crucial to follow a consistent maintenance schedule. While exact intervals can vary depending on the vehicle’s make, model, and usage, a general rule of thumb is to inspect the hydraulic system every 6,000 to 12,000 miles or twice a year—whichever comes first.

For daily drivers or vehicles frequently used in heavy traffic, regular hydraulic fluid checks and hose inspections should be done closer to the 6,000-mile mark. Off-road or performance vehicles may require even more frequent maintenance due to increased stress on automotive hydraulic components.

In addition to inspections, schedule hydraulic fluid replacement every 30,000 to 60,000 miles, or as recommended in your owner’s manual. Always check for signs of leaks, contamination, or pressure loss during every service.

Following this schedule helps maintain optimal system performance and ensures your car remains safe and responsive on the road.

Safety Precautions During Hydraulic System Maintenance

Working on hydraulic systems in cars can be dangerous if proper safety procedures aren’t followed. These systems operate under high pressure, and even a small mistake can lead to serious injury. That’s why safety should always come first.

Before performing any maintenance, depressurize the hydraulic system completely. Never attempt to disconnect hoses or open components while the system is pressurized. Use proper lockout/tagout procedures to ensure the system cannot be accidentally reactivated while you’re working on it.

Always wear protective gloves and eyewear, especially when checking for leaks or replacing components. Pressurized fluid can penetrate the skin and cause severe damage. Be cautious when inspecting hydraulic hoses for vehicles, as worn hoses may burst unexpectedly.

If you suspect a hydraulic fluid leak, never use your hand to check—use cardboard or paper instead. Respecting the power and pressure of these systems is key to staying safe while keeping your car running at its best.

A Final Word on Safety

Your car’s hydraulic systems are vital for safe driving. A few minutes of regular inspection can save you from dangerous situations and expensive repairs. By keeping an eye on the fluid, hoses, and overall performance, you ensure your car remains as responsive and reliable as the day you got it.

Frequently Asked Questions

What do hydraulic systems do in a car?

They power critical functions like braking and steering by using pressurized fluid to multiply force, making the car easier and safer to control.

How do I know if my hydraulic system is failing?

Common signs include a soft or “spongy” brake pedal, difficulty steering, visible fluid leaks under the car, or low fluid levels in the reservoir.

How often should I change my car’s hydraulic fluid?

Check the fluid level monthly and inspect its condition. As a general rule, replace the fluid every 30,000 to 60,000 miles, or if it appears dark, dirty, or contaminated. Always consult your owner’s manual for specific intervals.

Can I fix a hydraulic leak myself?

While you might be able to tighten a loose fitting, most leaks from hoses or seals require professional repair due to the high pressures involved. It’s often safer to have a mechanic handle it.