Your vehicle’s suspension system is more than just a set of springs and shocks. Among its essential components are ball joints—small but mighty parts that play a crucial role in ensuring your car runs smoothly and safely. Think of ball joints as the pivot points connecting key suspension components like control arms and steering knuckles. They allow your wheels to move up and down, while also enabling smooth steering.

Without functional ball joints, your car’s handling and ride quality would be severely compromised. Over time, wear and tear can lead to issues, making it essential to understand how ball joints work and how to maintain them. Whether you’re a car enthusiast or just looking to keep your vehicle in top shape, this guide will walk you through the importance, types, symptoms of wear, and maintenance tips for ball joints in suspension systems.

- Understanding Ball Joints

- Types of Ball Joints

- Function of Ball Joints in Suspension Systems

- Common Symptoms of Worn or Failing Ball Joints

- Causes of Ball Joint Wear and Failure

- Inspection and Maintenance Tips for Ball Joints

- Ball Joint Replacement: When and How

- Preventive Measures to Extend Ball Joint Lifespan

- Conclusion

- Frequently Asked Questions About Ball Joints

Understanding Ball Joints

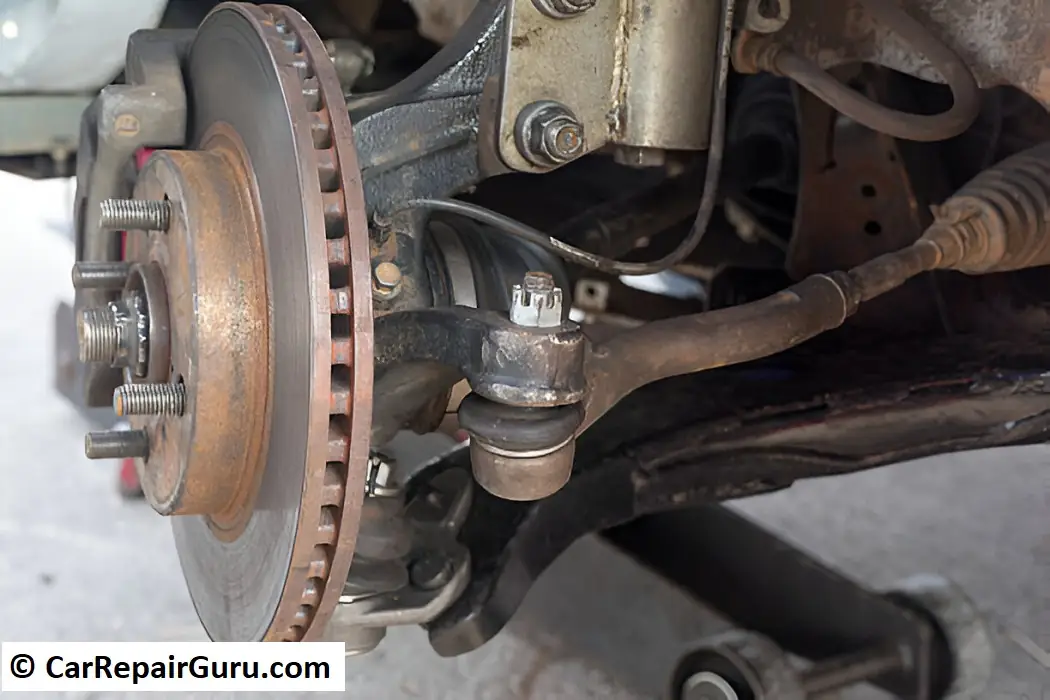

Ball joints are a vital component of a vehicle’s suspension system, acting as the connective pivot between the control arms and the steering knuckles. Essentially, they function as a spherical bearing in a socket, allowing your wheels to move up and down while enabling smooth side-to-side steering. This dual motion ensures that your car maintains optimal handling, stability, and comfort on various terrains.

To better understand how ball joints work, think of them like the ball-and-socket joints in the human body, such as the shoulder or hip. In the same way that your shoulder allows for a wide range of motion while keeping your arm securely in place, a ball joint provides flexibility and control to your vehicle’s suspension.

The ball portion of the joint fits snugly into a socket, and together, they enable precise movement while absorbing shocks from the road. This connection also supports the weight of your vehicle, especially in load-bearing ball joints, making them critical for both steering and suspension performance.

Understanding the mechanics of ball joints not only helps you appreciate their importance but also highlights why regular inspection and maintenance are crucial for vehicle safety and longevity.

Types of Ball Joints

Ball joints come in various types, each serving a specific purpose in a vehicle’s suspension system. Understanding these types can help you recognize their importance and maintain them effectively.

Upper and Lower Ball Joints

In most vehicles, the suspension system includes both upper and lower ball joints. The upper ball joint connects the upper control arm to the steering knuckle, while the lower ball joint serves the same function on the lower control arm. The lower ball joint typically bears more load, making it more susceptible to wear and tear over time.

Load-Bearing vs. Non-Load-Bearing Ball Joints

Load-bearing ball joints, as the name suggests, support the vehicle’s weight. They play a critical role in maintaining stability and proper alignment. On the other hand, non-load-bearing ball joints do not carry weight but facilitate the movement of suspension components, ensuring smooth steering and suspension action.

Compression-Loaded and Tension-Loaded Ball Joints

Ball joints can also be categorized by the direction of force they experience. Compression-loaded ball joints bear downward pressure, often found in vehicles with certain types of suspension designs. Conversely, tension-loaded ball joints handle upward forces, common in different suspension setups.

Each type of ball joint is essential for specific tasks, and their condition directly impacts your vehicle’s performance and safety. Knowing their differences helps ensure you’re prepared to inspect, maintain, or replace them as needed.

Function of Ball Joints in Suspension Systems

Ball joints are the unsung heroes of a vehicle’s suspension system. Their primary function is to connect the control arms to the steering knuckles, creating a pivot point that allows these components to move together seamlessly. This connection is crucial for maintaining stability and ensuring that your wheels respond accurately to steering inputs.

One of the most critical roles of ball joints is facilitating smooth steering and suspension movement. As you drive, the suspension system absorbs shocks from uneven road surfaces while the steering mechanism adjusts the wheel angles to follow your commands. Ball joints enable this dual motion, allowing the wheels to move up and down with the suspension while pivoting side to side for steering. This flexibility ensures that the suspension system operates efficiently, even under demanding conditions.

The condition of ball joints directly impacts vehicle handling and ride comfort. Worn or damaged ball joints can lead to issues like loose steering, uneven tire wear, and poor vehicle alignment. These problems not only compromise safety but also reduce ride quality, making the car feel unstable or rough. On the flip side, well-maintained ball joints help your car maintain precise steering, smooth suspension movement, and a comfortable ride, ensuring an enjoyable driving experience.

By understanding the essential role of ball joints in the suspension system, you can better appreciate their importance and the need for regular inspections to prevent performance issues.

Common Symptoms of Worn or Failing Ball Joints

Ball joints are crucial for smooth driving, but like any mechanical component, they wear out over time. Recognizing the symptoms of failing ball joints early can save you from costly repairs and safety risks. Here are the most common signs to watch for:

Uneven Tire Wear

One of the earliest indicators of ball joint wear is uneven tire wear. When ball joints lose their integrity, they can cause misalignment in the suspension system. This uneven distribution of weight and pressure on the tires results in irregular wear patterns, shortening their lifespan.

Clunking Noises from the Front Suspension

A distinct clunking or knocking sound coming from the front suspension, especially when driving over bumps or uneven surfaces, is often a telltale sign of failing ball joints. This noise occurs because the ball joint is loose and allows excessive movement in the suspension components.

Steering Wheel Vibrations

When ball joints wear out, they can create slack in the connection between the control arms and steering knuckles. This looseness may result in vibrations felt through the steering wheel, particularly at higher speeds.

Vehicle Drifting to One Side

Faulty ball joints can affect the alignment of your wheels, causing your vehicle to pull or drift to one side. This not only makes driving more difficult but also poses a safety hazard if not addressed promptly.

If you notice any of these symptoms, have your ball joints inspected immediately to ensure your vehicle remains safe and functional.

Causes of Ball Joint Wear and Failure

Ball joints are built to withstand tough conditions, but they are not immune to wear and failure. Understanding the common causes of ball joint deterioration can help you take preventive measures to extend their lifespan.

Exposure to Road Debris and Contaminants

Ball joints are located near the wheels, making them highly susceptible to dirt, dust, and road debris. Over time, these contaminants can penetrate the protective seals around the joint, causing internal damage. Once dirt mixes with the grease inside, it accelerates wear and reduces the ball joint’s efficiency.

Lack of Lubrication

Proper lubrication is essential for ball joint function. Grease minimizes friction between the ball and socket, allowing smooth movement. If the protective boot around the joint is damaged, grease can leak out, leading to increased friction and eventual failure. Regular inspection and timely re-lubrication can prevent this issue.

Normal Wear and Tear Over Time

Like any mechanical part, ball joints naturally wear out due to prolonged use. The constant movement and pressure they endure—especially in load-bearing joints—gradually weaken their structure. High-mileage vehicles are particularly prone to ball joint wear, making regular maintenance crucial.

By addressing these causes proactively, such as maintaining lubrication and protecting the joints from contaminants, you can prevent premature failure and ensure your suspension system operates optimally.

Inspection and Maintenance Tips for Ball Joints

Keeping your ball joints in good condition is essential for maintaining a safe and smooth driving experience. Regular inspection and maintenance can help you identify issues early, prolonging the lifespan of your suspension system.

Regular Visual Inspections

Begin by performing regular visual checks of your ball joints and their protective boots. Look for visible cracks, tears, or leaks in the rubber boot that protects the joint. Any sign of grease leakage or dirt buildup around the joint is a red flag and requires attention.

Listening for Unusual Noises

Pay attention to your vehicle while driving. Clunking or knocking noises, especially when driving over bumps or uneven roads, can indicate worn or failing ball joints. These sounds occur because of excessive movement or looseness in the joint and should not be ignored.

Checking for Excessive Play or Movement

You can test for excessive play by jacking up the vehicle and manually moving the wheel. Grip the tire at the top and bottom and try to rock it. If there’s noticeable movement or looseness, the ball joint may be worn out. Be sure to perform this test carefully or have it done by a professional.

Importance of Professional Inspections During Routine Maintenance

While DIY inspections are helpful, professional maintenance is crucial. Mechanics have specialized tools to measure ball joint wear accurately. They can also check for alignment issues caused by worn ball joints. Including ball joint inspections in routine maintenance ensures small problems don’t escalate into major safety hazards.

By adopting these practices, you can maintain the integrity of your ball joints, enhance your vehicle’s performance, and avoid costly repairs. Proactive care is key to ensuring a safe and comfortable driving experience.

Ball Joint Replacement: When and How

Replacing ball joints is a critical maintenance task that ensures your vehicle’s suspension system operates safely and efficiently. Here’s what you need to know about when and how to replace ball joints.

Signs Indicating the Need for Replacement

Several warning signs indicate it’s time to replace ball joints. Common symptoms include clunking noises from the front suspension, uneven tire wear, and excessive play or looseness in the joint. Steering wheel vibrations and the vehicle drifting to one side can also signal worn-out ball joints. If you notice these issues, a timely replacement is essential to prevent further damage and maintain safe driving conditions.

Overview of the Replacement Process

Ball joint replacement requires specific tools and expertise. The process typically involves:

- Lifting the Vehicle: Use a jack to safely raise the vehicle and remove the wheel to access the suspension components.

- Removing the Ball Joint: Detach the control arm and steering knuckle. Depending on the design, the ball joint may be pressed, bolted, or riveted into place.

- Installing the New Ball Joint: Secure the new ball joint, ensuring proper alignment, and reassemble the suspension components.

- Testing: After installation, test the vehicle for proper functionality and perform an alignment if necessary.

While DIY replacement is possible for experienced mechanics, it’s often safer and more efficient to have a professional handle this task.

Importance of Using Quality Replacement Parts

Not all ball joints are created equal. Investing in high-quality replacement parts ensures durability, performance, and safety. Cheap or substandard ball joints can fail prematurely, putting you at risk of accidents and costly repairs.

Safety Considerations During Replacement

Replacing ball joints requires handling heavy vehicle components and precise alignment. Always use appropriate tools, follow safety protocols, and secure the vehicle properly. If you’re unsure, consult a professional to avoid mistakes that could compromise your safety.

Regular inspection and timely replacement of ball joints keep your vehicle running smoothly, ensuring safety and reliability on the road.

Preventive Measures to Extend Ball Joint Lifespan

Ball joints are durable but not indestructible. With proper care, you can extend their lifespan and ensure your suspension system performs optimally. Here are some effective preventive measures:

Regular Maintenance and Lubrication

One of the most critical steps in maintaining ball joints is regular lubrication. Many modern ball joints come sealed, but if yours are serviceable, periodic greasing can minimize friction and reduce wear. Additionally, inspect the protective rubber boots during maintenance to ensure they’re intact and keeping contaminants out.

Avoiding Rough Driving Conditions When Possible

Driving on rough roads, potholes, or off-road terrain puts extra stress on ball joints. While unavoidable at times, minimizing exposure to such conditions can significantly reduce wear and tear. Slow down when driving over bumps or uneven surfaces to limit the impact on your suspension components.

Ensuring Proper Wheel Alignment

Misaligned wheels increase stress on ball joints and other suspension parts, leading to premature wear. Regularly checking and adjusting your wheel alignment ensures that your ball joints distribute weight evenly and function as intended. It also improves tire longevity and overall handling.

By following these preventive measures, you not only extend the lifespan of your ball joints but also enhance your vehicle’s safety, handling, and ride quality. Proactive care saves money and prevents major repairs down the road.

Conclusion

Ball joints are a cornerstone of your vehicle’s suspension system, enabling smooth steering, stable handling, and a comfortable ride. Their ability to connect the control arms to the steering knuckles while facilitating multi-directional movement is vital for safe and efficient driving.

Neglecting ball joint maintenance can lead to issues such as uneven tire wear, poor alignment, and even complete suspension failure. Regular inspections, proper lubrication, and timely replacements are essential to prevent these problems and maintain your vehicle’s performance and safety.

By understanding how ball joints work, recognizing signs of wear, and taking proactive care measures, you can extend their lifespan and avoid costly repairs. Prioritizing ball joint health is an investment in your car’s reliability and your peace of mind on the road.

Frequently Asked Questions About Ball Joints

What are the signs of a bad ball joint?

Common symptoms of a failing ball joint include clunking noises from the front suspension, uneven tire wear, steering wheel vibrations, and the vehicle pulling to one side. If you notice any of these signs, have your ball joints inspected immediately to avoid further damage.

How often should ball joints be inspected?

It’s recommended to inspect ball joints during routine maintenance or at least every 12,000 to 15,000 miles. High-mileage vehicles or those driven in harsh conditions may require more frequent checks.

Can I drive with a bad ball joint?

Driving with a worn or damaged ball joint is unsafe. A failed ball joint can cause loss of control over the vehicle, leading to accidents. Address any signs of wear promptly to ensure your safety.

How much does it cost to replace ball joints?

The cost to replace ball joints typically ranges from $100 to $400 per joint, including parts and labor. Factors such as vehicle make, model, and whether additional suspension components need replacement can influence the price.

Are there different types of ball joints for different vehicles?

Yes, ball joints vary depending on the vehicle’s suspension design. Some vehicles use load-bearing ball joints, while others have tension- or compression-loaded types. Always use the correct type for your vehicle to ensure proper performance.