The Anti-Lock Braking System (ABS) is one of the most essential safety innovations in modern vehicles. Imagine driving on a rainy day or maneuvering through icy roads — without ABS, a sudden brake could cause your wheels to lock up, leading to dangerous skidding and loss of control. ABS prevents this by ensuring your wheels maintain traction with the road surface, even during hard braking, reducing the risk of accidents.

ABS is not just about safety; it also enhances vehicle handling. By preventing wheel lock-up, it allows drivers to maintain steering control during emergency stops. This system is especially crucial in slippery conditions, where traditional braking systems might struggle to perform effectively.

So, how does ABS work? At its core, the system uses sensors placed on each wheel to monitor speed and detect any potential lock-up. When a wheel starts to lock, the ABS module intervenes by rapidly pulsing the brake pressure on that wheel. This process, often felt as a pulsation in the brake pedal, helps the wheel regain traction almost instantly.

ABS has become a standard feature in most vehicles today, offering peace of mind to drivers and passengers alike. Understanding how it works is the first step toward ensuring it functions correctly when you need it most.

Common Symptoms of ABS Malfunctions

An Anti-Lock Braking System (ABS) is designed to enhance safety, but like any mechanical system, it can experience issues over time. Recognizing the symptoms of ABS malfunctions can help you address problems before they escalate.

ABS Warning Light Activation

One of the most obvious signs of an ABS malfunction is the illumination of the ABS warning light on your dashboard. This light indicates that the system has detected a fault, such as a failed sensor, damaged wiring, or issues with the ABS module. While your brakes might still function, the safety benefits of ABS won’t be available until the issue is resolved. Ignoring this warning could lead to compromised braking performance in critical situations.

Unresponsive Brake Pedal

A hard or unresponsive brake pedal is another symptom of ABS problems. This could result from a faulty hydraulic pump or issues within the brake lines. When the ABS system fails to regulate brake pressure, it can make braking feel unusually stiff, requiring greater effort to bring the vehicle to a stop. If you notice this, it’s essential to have your braking system inspected promptly.

Pulsating Brake Pedal During Braking

While a pulsating brake pedal is normal during ABS activation, experiencing this sensation during regular, moderate braking could indicate an underlying problem. Abnormal pulsations might result from damaged wheel speed sensors or an issue with the ABS hydraulic system. These irregularities can affect the system’s ability to perform correctly.

Decreased Braking Performance

A noticeable reduction in braking efficiency, such as longer stopping distances or difficulty maintaining control during emergency stops, can signal ABS failure. Common causes include worn hydraulic components or a malfunctioning ABS module. When braking performance is compromised, your safety on the road is at risk.

By identifying these symptoms early, you can ensure timely repairs and maintain the reliability of your ABS.

Common Causes of ABS Issues

The Anti-Lock Braking System (ABS) relies on several interconnected components to function properly. When one or more of these components fail, the system may become compromised, leading to unsafe driving conditions. Here are the most common causes of ABS issues and how they affect the system.

Faulty Wheel Speed Sensors

Wheel speed sensors are critical to the ABS, as they monitor the rotational speed of each wheel. These sensors send data to the ABS module, allowing it to detect potential wheel lock-up. Over time, wheel speed sensors can fail due to dirt, debris, or physical damage. A faulty sensor may send incorrect data—or no data at all—causing the ABS warning light to activate and reducing the system’s effectiveness.

Damaged ABS Module

The ABS module acts as the system’s brain, processing information from the sensors and regulating brake pressure as needed. Damage to the module, whether due to electrical issues, water ingress, or corrosion, can disrupt communication between the components. This can lead to erratic ABS performance or complete system failure. A malfunctioning module often requires immediate replacement to restore functionality.

Hydraulic Pump Malfunctions

The hydraulic pump is a vital part of the ABS, responsible for managing brake fluid pressure during operation. When the ABS activates, the pump quickly increases or decreases pressure to prevent wheel lock-up. Over time, wear and tear can impair the pump’s efficiency or cause it to fail entirely, resulting in uneven brake performance or longer stopping distances.

Worn Hydraulic Valves

Hydraulic valves control the flow of brake fluid within the system, enabling precise modulation of pressure to each wheel. If these valves become worn or clogged, the ABS may struggle to regulate brake pressure effectively, leading to inconsistent braking. Regular maintenance can help detect and address valve issues before they cause system-wide problems.

Electrical Wiring Problems

Electrical wiring is the backbone of the ABS, connecting sensors, the module, and other components. Damaged or corroded wiring can disrupt communication, causing the ABS warning light to illuminate and impairing system functionality. Wiring issues are often overlooked but can have significant consequences if not addressed.

Understanding these common causes can help drivers maintain their ABS and avoid costly repairs, ensuring the system performs optimally when it’s needed most.

Step-by-Step ABS Troubleshooting Guide

When your Anti-Lock Braking System (ABS) malfunctions, it’s essential to diagnose the issue promptly to maintain vehicle safety. This guide walks you through the steps to identify and resolve common ABS problems.

Initial Diagnostic Steps

The first step in ABS troubleshooting is to check for error codes using an OBD-II scanner. Modern vehicles store diagnostic trouble codes (DTCs) that pinpoint specific issues within the ABS system. Connect the scanner to your vehicle’s diagnostic port, typically located under the dashboard. Review the codes displayed to determine which components require further inspection. Keep in mind that multiple codes may indicate interrelated issues.

Inspecting Wheel Speed Sensors

Faulty wheel speed sensors are a common cause of ABS problems. Begin by visually inspecting the sensors located near each wheel. Look for signs of dirt, debris, or physical damage. Clean the sensors carefully, as grime can interfere with their functionality. Next, use a multimeter to test the sensors’ electrical output. If a sensor is not transmitting signals correctly, it may need to be replaced. Ensure the wiring connected to the sensors is intact and free from corrosion.

Evaluating the ABS Module

The ABS module is the system’s control center, and a malfunction here can disrupt the entire system. Start by ensuring the module is receiving power and is free from corrosion or water damage. Use a diagnostic scanner capable of ABS testing to check the module’s functionality. If the scanner indicates a failure or if the module does not respond, it may need to be repaired or replaced. Professional evaluation is recommended for this step, as module replacement can be complex.

Checking Hydraulic Components

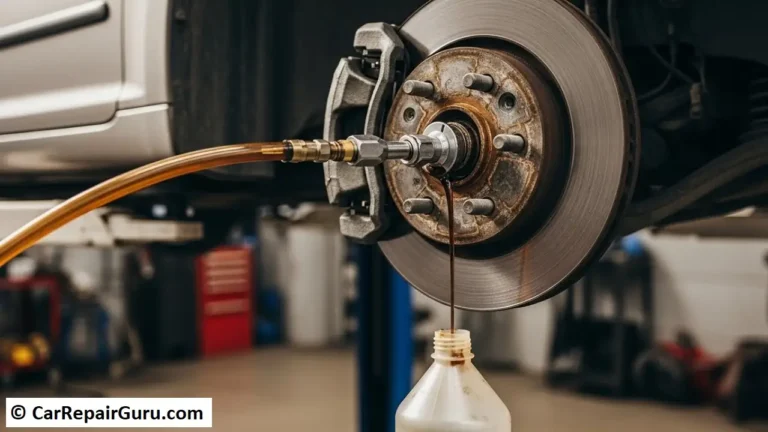

The hydraulic pump and valves are critical for regulating brake pressure. Begin by inspecting the hydraulic pump for signs of leaks or physical damage. Listen for unusual noises when the ABS activates, as these could indicate pump failure. Check the brake fluid levels and ensure the fluid is clean. Contaminated or low fluid can impair hydraulic performance. For the valves, look for blockages or signs of wear. A faulty valve can prevent the proper modulation of brake pressure.

Assessing Electrical Connections

Electrical issues can disrupt communication within the ABS system. Inspect the wiring harnesses and connectors for signs of wear, corrosion, or damage. Pay close attention to areas near the sensors and module. Use a multimeter to check for continuity and ensure that power is flowing correctly through the circuits. Repair or replace any damaged wiring to restore connectivity.

By following these troubleshooting steps, you can identify and resolve ABS issues effectively. Regular maintenance and prompt attention to warning signs can help ensure your ABS operates reliably, keeping you safe on the road.

Preventative Maintenance for ABS

Maintaining your Anti-Lock Braking System (ABS) through regular preventative care is essential for ensuring its optimal performance and longevity. Here are some key practices to keep your ABS in top condition.

Regular System Inspections

Periodic inspections of your ABS are crucial for catching potential issues early. Schedule routine checks with a qualified mechanic to examine the system’s components, including the module, sensors, and hydraulic parts. During these inspections, ensure diagnostic scans are performed to detect any stored error codes. Addressing minor issues promptly can prevent costly repairs and reduce the risk of ABS failure during critical moments.

Keeping Sensors Clean

Wheel speed sensors play a pivotal role in ABS functionality, but they are often exposed to dirt, debris, and road grime. To prevent malfunctions, clean these sensors regularly. A simple wipe with a soft cloth or a gentle brush can remove accumulated dirt. Avoid using harsh chemicals or abrasive tools that could damage the sensors. If you frequently drive in muddy or snowy conditions, increase the frequency of cleaning to keep sensors functioning effectively.

Ensuring Proper Brake Fluid Levels

Brake fluid is the lifeblood of the ABS, enabling the hydraulic pump and valves to regulate pressure efficiently. Check brake fluid levels regularly and top them off if necessary. Use the type of fluid recommended by your vehicle manufacturer, as using the wrong fluid can harm the system. Additionally, replace brake fluid according to the manufacturer’s maintenance schedule to prevent contamination that could impair ABS performance.

By incorporating these preventative measures into your routine maintenance, you can extend the life of your ABS and ensure it’s ready to perform when you need it most. A well-maintained ABS system not only enhances safety but also provides peace of mind on every journey.

When to Seek Professional Help

While some ABS issues can be resolved with basic troubleshooting, others require the expertise of a professional mechanic. Knowing when to seek help can save time, money, and ensure your safety on the road.

Identifying Complex Issues

Certain ABS problems are too complex for a DIY approach. For instance, persistent ABS warning lights after sensor replacement or difficulty diagnosing issues through error codes might point to problems with the ABS module or hydraulic components. If you notice inconsistent braking performance, unusual noises during braking, or if the system fails to activate in slippery conditions, it’s time to consult a professional. Additionally, repairing or replacing major components like the ABS module or hydraulic pump often requires specialized tools and expertise.

Choosing a Qualified Mechanic

Selecting the right mechanic is crucial for addressing ABS issues effectively. Look for technicians with experience in ABS diagnostics and repair. Certification from reputable organizations, such as ASE (Automotive Service Excellence), can indicate expertise in modern braking systems. Reading online reviews or seeking recommendations from trusted sources can help you find a reliable professional. Ensure the mechanic uses advanced diagnostic tools and offers a clear explanation of the repairs needed.

By entrusting complex ABS problems to a qualified expert, you can ensure that the system is repaired accurately and safely.

Conclusion

Maintaining and promptly addressing issues with your Anti-Lock Braking System (ABS) is essential for ensuring your safety and that of others on the road. Regular inspections, proper care of components like sensors and hydraulic parts, and maintaining optimal brake fluid levels can prevent most common problems. When issues arise, timely troubleshooting and professional assistance for complex problems are key to keeping your ABS functioning effectively. By prioritizing ABS maintenance, you can drive with confidence, knowing your braking system will perform reliably in critical moments and enhance your overall vehicle safety.

FAQs about ABS Troubleshooting

What Does It Mean When the ABS Light Is On?

The ABS light signals a system issue, such as faulty sensors, low brake fluid, or module problems. It disables ABS, leaving only standard braking.

Can I Drive with the ABS Light On?

While you can drive, it’s unsafe as ABS benefits are lost. Promptly addressing the issue ensures better control in emergencies.

How Often Should I Service My ABS?

Service ABS components every 12,000–15,000 miles or as recommended. Regular checks prevent major failures.

What Are the Costs Associated with ABS Repairs?

Costs range from $100–$1,500 depending on the issue, with diagnostics adding $50–$150. Regular maintenance reduces repair expenses.

How Do I Reset My ABS Light?

Reset after fixing issues using an OBD-II scanner. If it persists, further diagnostics are needed.

Can ABS Fail Suddenly?

Though rare, sudden failures can occur due to severe damage or leaks. Regular maintenance reduces risks.